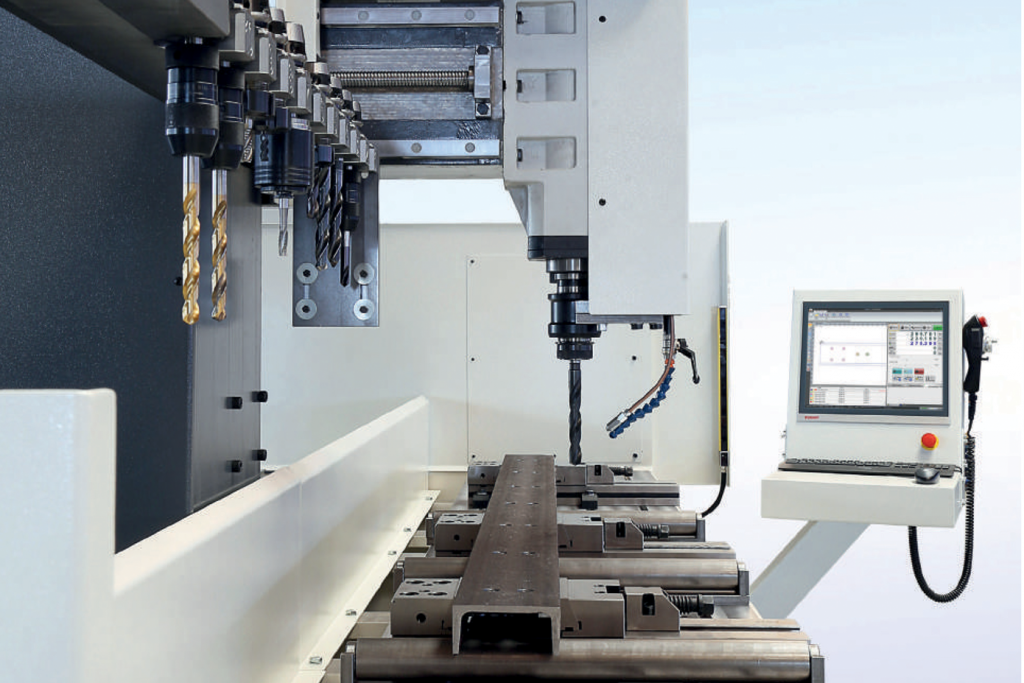

Machine

- Body Fabricated & Stress relieved

- Bed Size 2000X3000 mm

- Clamping - Hydraulic

- LM Guides & blocks - Hiwin

- Spindle Motor – 7.5 Kw

- Spindle taper – BT-40

- Spindle speed 0 to 3000 rpm

| Particulars | |

|---|---|

| Spindle accuracy | 5 Micron |

| Drill Dia. | 0.5 mm to 40mm |

| Spindle motor | 1 KW to 7.5 KW Induction motor |

| Drill speed (Max) | 8000 rpm |

| Stroke | 150 to 300 |

| Feed motor | 400W to 3 KW AC Servo |

| Linear Operation (Optional) | Available as per requirement |

| Rapid Approach | 300mm/sec Max |

| Cutting speed | 0.1 mm/rev |

| X, Y, Z | Available as per requirement |

| Job clamping/Holding | Hydraulic /Manual/ Pneumatic |

| Job Loading/Unloading | Manual / Auto |

Neptune Systems is Leading Manufacturer & Supplier of CNC Machine in India. High rigid & long stroke (up to 300 mm) drill units with compact size, variety of models available for wide range of machining requirements High quality servo motor for feed & precise ball screw designed eliminate feed rate fluctuation of feed speed by drilling forces; less burr generation for through hole drilling and longertool life, High precision, high efficiency, less space and cost reduction that are Critical for the machining operation can be gained. Neptune system is the most trusted brand among CNC Machine Manufacturers in India.

| Particulars | |

|---|---|

| Spindle accuracy | 5 Micron |

| Drill Dia. | 0.5 mm to 26mm |

| Spindle motor | .700 Kw to 3.7 Kw Brushless DC |

| Drill speed (Max) | 6000 |

| Stroke | 300 |

| Linear Operation (Optional) | Available as per requirement |

| Particulars | |

|---|---|

| Feed motor | 400 Kw to 2.7 Kw AC Servo |

| Rapid Approach | 300mm/sec Max |

| Cutting speed | 16.7 mm/sec |

| X, Y, Z | Available as per requirement |

| Job clamping/Holding | Hydraulic / Pneumatic |

| Job Loading/Unloading | Manual / Auto |

Suitable for drilling extremely deep holes & small dia. Versatile machines to compliment job shops / dedicated machines for high volume production drill sizes ranging from 1.5 mm to 25 m Allows high level flexible for accommodating range of standard components.

| Particulars | |

|---|---|

| Drill Dia Range | 5 to 25 mm |

| Spindles | 1-2-4 |

| Spindle motor / Spindle( HP) | 5 to 10 |

| Drill Depth (mm) | 400/600/1000 |

| Drill Feed Range mm/min | 0-1000 |

| Spindle Speed Range (RPM) | 500 t0 6500 |

| Components OD | 800 mm |

| Particulars | |

|---|---|

| Rapid Approach | 300mm/sec Max |

| Cutting speed | 16.7 mm/sec |

| X, Y, Z | Available as per requirement |

| Job clamping/Holding | Hydraulic / Pneumatic |

| Job Loading/Unloading | Manual / Auto |

Compared to the years we have been developing control technology and machining centres, our nearly decade long experience may seem short. However, we've leveraged our overall machine tool experience and efficient process approach to ensure that each decision we make meets our objective to deliver manufacturing technology that helps our customers increase profitability. We know that premium components and expert design are critical in machine tool development. Therefore, you will have the peace of mind that our HMC’s will be reliable and rigid.

Design + Construction: We use thick-walled, fine-grain cast iron for the major structural assemblies (base, head stock, and cross Casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting. The box type cross slide ensures the turret remains rigid and stable even during the most rigorous cycles. We also use extra wide linear guide ways that are strategically spaced to provide excellent support to the cross slide.

Our horizontal machining centre is optimum for low to medium-batch or large parts manufacturing production runs. The design promotes better chip control—gravity does the work with chips falling effortlessly. We design & manufacture wide range of HMC’s & VMC’s as per requirements designed fully integrated pallet changing system for higher production runs. We offer HMC’s /VMC’s of superior capabilities at affordable prices and the user friendly control makes setups and programs you will find our HMC’s are the perfect job shop machines for those looking for return on investment in less time than ever before.

| Particulars | |

|---|---|

| Main Performance and Technical Data | 500x450 |

| X/Y/Z travel(mm) | 900×450×500 |

| Distance from spindle nose to table surface(mm) | 140 approx. |

| Spindle type | BT40 |

| Spindle diameter | 100 |

| Spindle speed(r/min) | 6000 RPM |

| Spindle braking time | ≤4S |

| Spindle | HAAS Equivalent |

| Particulars | |

|---|---|

| Spindle power(HP) | 7.5 |

| Ball screw Ball screw support bearing Positioning accuracy(mm) |

HIWIN NSK/SKF 0.01 |

| Repeatability(mm) | 0.06 |

| Parallelism between X axis and B axis (swivel to any angle | ≤0.02 |

| Rapid Traverse speed(mm/min) | ≥15000mm/min |

| Cutting feed rate | 8000mm/min |

Yoke is a part of Drive Shaft which is required when power is to be transmitted from engine to differential of an automobile. A yoke for a universal joint is used to join fork halves; each comprising a base component and a bearing component.During drilling and spot facing on the flanges of Yoke, vibrations takes place and it leads to tool breakage. Hence the tool changing time is increased. Thus there is a need to design a fixture to nullify the problems. We have designed such a fixture which will carry out the drilling operation efficiently. The newly designed fixture uses an insert type of drilling U drill which removes the material as per requirement, which reduces the vibrations and tool breakage and ultimately reduces the tool changing time

Spot facing: Spot facing is the operation of smoothing and squaring the surface around and at the end of a hole so as to provide a smooth seat for a nut or for the head of a cap screw. Spot facing is generally done on castings and forgings.

| Particulars | |

|---|---|

| Max Drill size | 50mm |

| Spindle speed | 3000rpm |

| Spindle Nose | BT 40 |

| Spindle motor | 5HP |

| Drive | Through timer, belt and pulley |

| Travel | 100mm |

| LM Guides and Ball screw | Hiwin |

PCB Drilling & routing CNC Machine offered come designed and developed using latest technology support and provides for reliable and consistent performance. Some of its features include: