Neptune systems have arrangement with TEJ controls

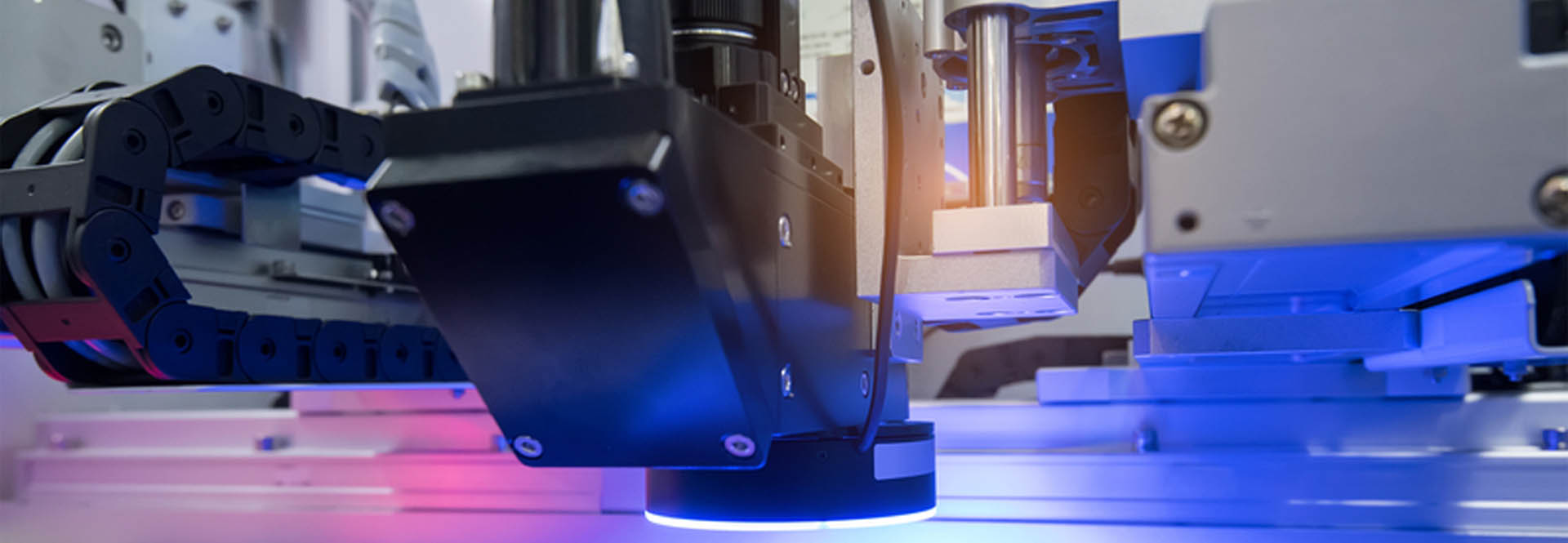

Thane who are pioneer in vision systems, Vision

Inspection Systems uses camera to grab image

of the component to be tested, once image is

taken Image Processing Algorithms are used to

detect any visual flaws in component. Vision

Inspection systems can be used for faster and

accurate automated visual inspection. The typical

examples of vision inspection systems include

automated sorting systems, Automated Optical

Inspection (AOI), Automated Optical Measurements

(AOM), Pattern Matching, Optical Character

Recognition (OCR), Colour Inspection or colour

matching, Go - No Go inspection systems etc.

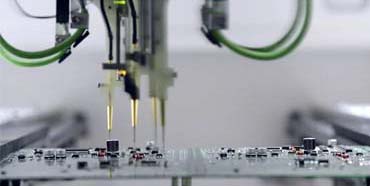

We provide vision inspection systems using National

Instruments Vision Development Module and we work

with various cameras like NI smart camera, fire wire

cameras, GigE Cameras, USB cameras. We provide vision

inspection systems using National Instruments

Vision Development Module and we work with various

cameras like NI smart camera, fire wire cameras,

GigE Cameras, USB cameras. We listen to your

requirements and develop a customized solution

which provides you with optimal cost quality and

performance. Depending on custom requirements we

design system & simulate depending on requirements

for any requirements don’t hesitate to ask for demos.

.jpg)