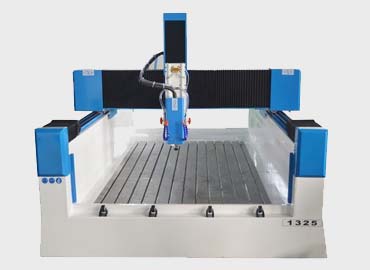

The metal engraving machine uses a laser beam to remove a specific portion of the metal material to achieve the desired effect or logo. In metal engraving applications, the laser beam is like a chisel used for engraving, cutting away excess metal material such as a small CNC engraving machine. Suitable materials are mold industry engraving, plastic mold industry, watch glasses industry, mobile phone manufacturing, fine die, bronzing die, high-frequency die, embossing wheel die and graphite electrodes, copper electrode processing. Neptune system manufactures, supplies, & exports laser engraving machines in Pune at an affordable price.

Features:

- Strong Steel

- Good Stability

- Large Bearing Capacity