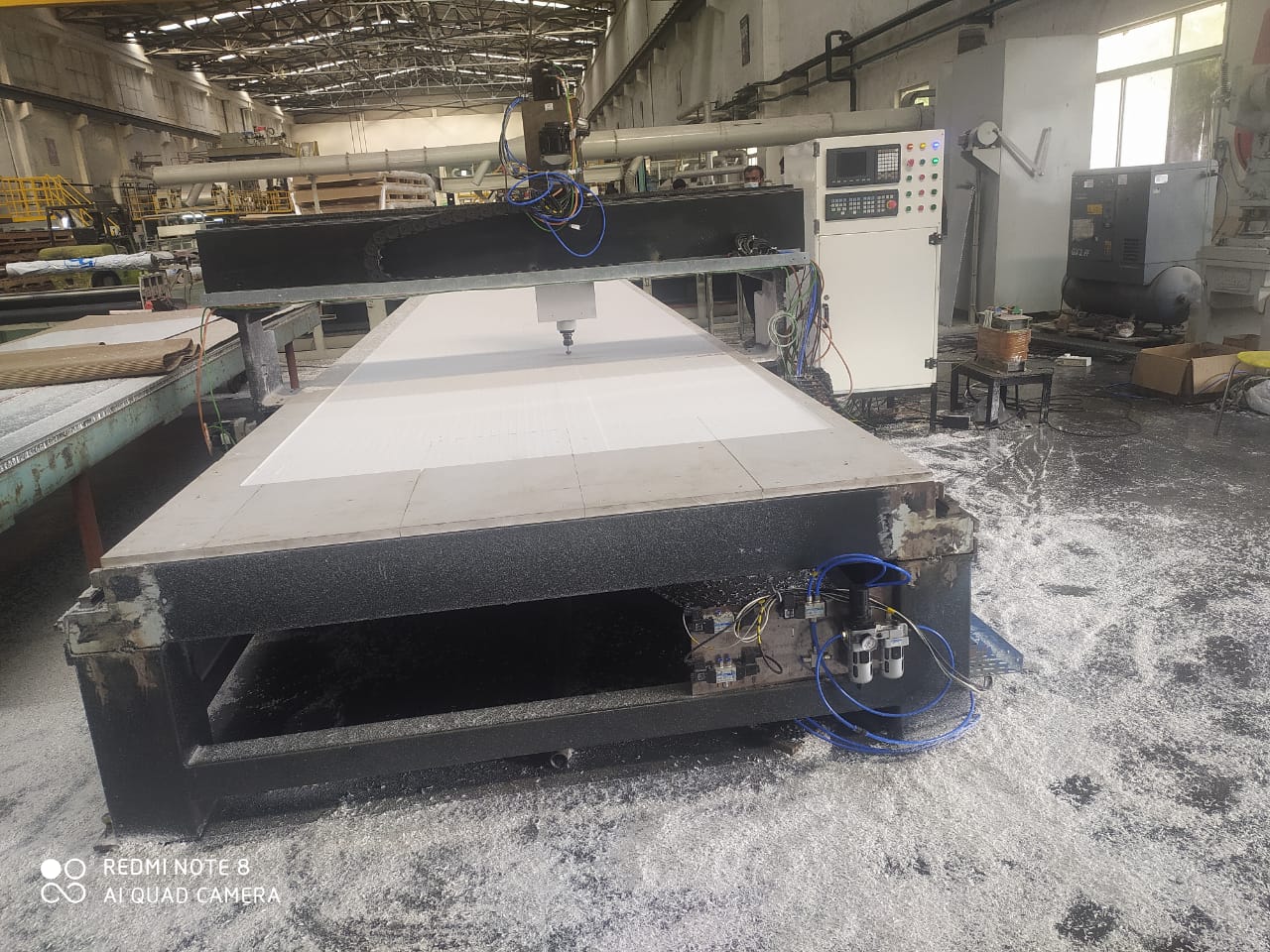

Machine Specifications:

- Bed Size: 1600mm * 6600 mm

- 6.6 Kw ATC Spindle

- 24,000 RPM

- Vacuum Bed and Dust Collector

- Clamping – Vacuum Suction

- Nose Rider

The 5 Axis Large Format Overhead Gantry CNC Machine is a continuous-use, heavy duty machine that is feature rich, and can be used to process a wide variety of applications ranging from foam to aluminium. This machine can be manufactured with a universal fixture table, which can perform multiple tasks withoutrequiring the user to stop production. The design of this machine allows for easy loading/unloading of large materials, as the front doors slide open and close. The universal fixture table gives your business the option to improve productivity by reducing downtime between part runs. This machine features an all steel frame, which is stress relieved and welded in-house to ensure the highest quality. Neptune system is a Manufacturer, Supplier, and Exporter of Special Purpose Machines from Pune.

| Particulars | |

|---|---|

| MODEL no. | TC- 2030 |

| Table Size : | 3400X5000 mm |

| Engraving Size : | 2000X3000 mm |

| Z – Axis travelling : | 1500mm |

| Feeding Height : | 1500 mm |

| Body : | Fabricated Steel Stress Relieved (12 mm Steel Plate) |

| Z – Axis : | U Shape CI Structure |

| Y- Axis wall : | 12 mm Steel Structure |

| X,Y,Z- Transmission : | 5010 Hiwin Double nut Auto anti Gap Ball nut |

| Particulars | |

|---|---|

| X- Axis Gantry : | 12 mm Steel Structure |

| LM Rail : | 50 mm Hiwin |

| X,Y,Z,A& C – | Axis Motors YASKAWA Servo Motors |

| Spindle Speed – | 0 – 24000 RPM |

| Controller – | OSAI Italy |

| Working Speed : | 1500 mm/min |

| Resolution : | 0.001/Pulse |

| Tool Dia : | ISO 30 |

| Machine Power Supply : | 380 V, 50 Hz |

| Spindle Power : | 9.0 Kw |

The requirement may be for standard or special purpose, Neptune test machines capabilities is enhanced by our experience in automated production line equipment and process automation resulting in complete service to industry. Neptune Systems has the knowledge and expertise to assist the customers specify the acceptance leakage rate or limit and in designing and supply the leakage testing machine to reliably test how much an item is leaking. Different forms of leakage testing equipment supplied include manually loaded test benches to fully automatic leakage testing machines for 100% testing. Test methods include pneumatic leakage testing to hydro testing. If you have current projects that you are already looking at or you are considering improvements.

Neptune Systems designed & developed custom type Bearing Automation for Rieter India. Machine need to assemble following:

After loading Inner bearings on Gravity Chute, Plastic Rings on Stacker & Outer body on Indexing mechanism, operator simply press cycle start button Inner bearing gripper arm picks inner bearing, simultaneously second arm picks outer plastic from stacker places it on assembly area, during placing inner bearing by first pickingarm it checks whether plastic outer is placed on assembly area or not, after detecting plastic ring first picking arm advance for inner bearing insertion, after insertion first pick arm takes home position, Assembled sub assembly picked by picking cum main assembly arm and place & press it on outer casting body.