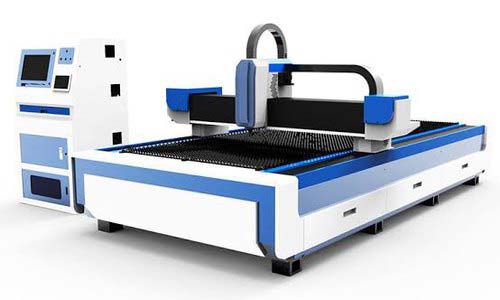

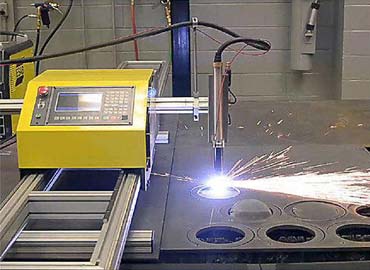

We are offering the best laser & plasma-cutting Machines from Pune, Maharashtra, India.

Cooling system with Automatic Alarm system.

Square rail and ball screw transmission enable machine high precision & stable performance

Optical components adopt imported USS 26 mirrors and ZNSE focus lens for high quality cutting effect.

Constant Optical source to fix the laser path ensure stable beam transmission.

Japan YASKAWA and PANASONIC servo motors and drives.